1. coating anticorrosive cold tape:

Polyethylene blown film for base material through the Corona and then dissolved in toluene solution of natural rubber coated, made after solvent residue adhesive film-coated cold tape. This type of tape, due to the manufacturing process is relatively simple, less investment in equipment, has the advantage of lower costs. Due to its production process and material limitations, there are often blown film strength finite, natural rubber, corona treatment of ageing ageing, adhesive coated very thin adhesive layer and basement membrane adhesion, Peel strength are low and often appear the phenomenon of degumming sticky on both sides. And toxic solvents toluene, likely to cause environmental pollution and damage to human health. Should be on a small scale life of shorter works.

2. type hot-melt coating anticorrosive cold tape:

With polyethylene film, polypropylene, glass cloth woven fabric or plastic-coated nonwoven substrate using modified bitumen after heating and melting of coating formed on the substrate. Modified bitumen is asphalt, such as adding a small amount of SBS thermoplastic elastomer, to improve the asphalt temperature sensitivity. This kind of tape due to modified asphalt, heat-resistance glass fiber cloth of asphalt anti-corrosion than before has greatly improved, and adhesive strength greatly. Because this tape of rubber layer material in the 80% is asphalt

components, its construction temperature should control in 5 ℃ to 50 ℃

Zhijian, dang below 5 ℃ Shi this class tape of asphalt rubber layer will

sent hard and lost viscous, dang above 50 ℃ Shi asphalt rubber layer

easy produced spill rubber flowing adhesion, thus its tape finished

volume in the must has isolation paper will asphalt rubber layer and

base material isolation. When this type of adhesive tape base material is fabric, because of grid spaces, its strength only 50% of polyethylene film tape for electrical insulation, so the tape thickness is usually more than 1 mm. Suitable environmental conditions, temperature changes in a smaller area.

3. compound polyethylene anticorrosive cold tape:

Used

polyethylene pressure extended film and butyl rubber rubber layer total

extrusion extended hot composite and into, due to used polyethylene

pressure extended process increased has base material polyethylene of

mechanical strength, butyl rubber has excellent of gas key sex (gas

penetration rate only natural rubber of 1/20), and in all rubber in the

butyl rubber has unique of since thaw stick received sex, to makes

polyethylene-butyl rubber composite type polyethylene anti-corrosion

tape has mechanical strength high, and stripping strength big, and

electrical strength high, and gas key sex good, and Wide temperature range (-30 c to 70 c), construction convenient, pollution-free and anticorrosive long life and has become widely used in the international mainstream anti-corrosion materials. United States of POLYKEN company, Italy's ALTA companies tens of thousands of tons of polyethylene tape tape are complex.

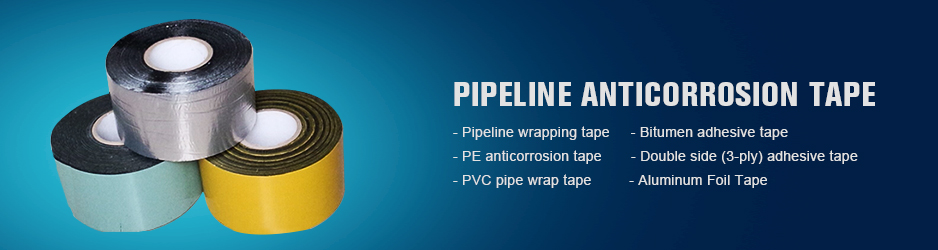

Tape wrapped around the cold, also known as cold tapes. Is based on the application of its construction can be wrapped at room temperature that is cold wrapped named. The tape is generally due to external corrosion materials as steel pipes widely used in the field of pipeline corrosion, often referred to duct tape wrapped around the cold, corrosion tape wrapped around the cold, pipeline corrosion tape, anticorrosive tape; the tape wrapped around the base of most cold polyethylene and production, it is also known as polyethylene tape wrapped around a cold.

Tape wrapped around the cold, also known as cold tapes. Is based on the application of its construction can be wrapped at room temperature that is cold wrapped named. The tape is generally due to external corrosion materials as steel pipes widely used in the field of pipeline corrosion, often referred to duct tape wrapped around the cold, corrosion tape wrapped around the cold, pipeline corrosion tape, anticorrosive tape; the tape wrapped around the base of most cold polyethylene and production, it is also known as polyethylene tape wrapped around a cold.